Description

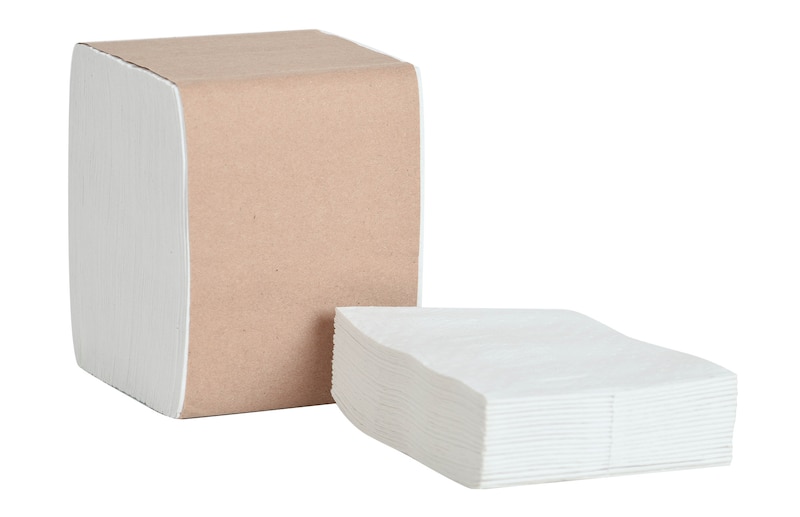

Run your business more efficiently. Tork Xpressnap Fit® Advanced Napkins are perfect for quick service food and drink restaurants. Tork Xpressnap Fit® not only serves more guests between refills – compared to tallfold and minifold systems – it also cuts inventory space and reduces unused napkins thrown-away by more than half. Tork Xpressnap Fit® Dispenser Napkins, White 2-ply are ideal for establishments that care about an enhanced guest experience.

- A napkin designed specifically for use with the Tork Xpressnap® Fit dispensing system.

- A space saving fold that opens to a full size napkin.

- Compact case which simplifies shipping and storage

- Unique pack solution, bundles are protected by a plastic bag for improved hygiene and handling

Product & Shipping data

Shipping data

Content

The product is made from

Recycled fibers

Chemicals

The packaging material is made from paper or plastic.

Material

Recycled fibers

Recycling of paper is an efficient use of resources as the wood fibers are used more than once.

High demands are put on quality and purity of recovered fibers, considering each step of the chain (collecting, sorting, transporting, storage, use), to ensure safe and hygienic products.

Recovered paper can be produced both from collected newsprint, magazines and office waste. The choice of recovered paper grades, is made for each product, depending on its specific requirements on performance properties and brightness. The paper is dissolved in water, washed and treated with chemicals under high temperature and screened to separate out impurities.

Bleaching is a cleaning process of the fibers that is often used. The aim is then to achieve a bright pulp, but also to get a certain purity of the fiber in order to achieve the demands for hygiene products and in some cases to meet the requirements for food safety.

Bleaching of the recovered pulp is made with chlorine-free bleaching agents (hydrogene peroxide and sodium dithionite). Except for Natural Napkins that are unbleached.

For bleached products we use bleaching agents (to increase the brightness of pulp from recovered paper).

Chemicals

All chemicals (process aids as well as additives) are assessed from an environmental, occupational health and safety and product safety point of view.

To control product performance we use additives:

- Wet strength agents (for Wipers and Hand Towels)

- Dry strength agents (is used together with mechanical treatment of the pulp to make strong products like wipers)

- For colored papers dyes and fixatives (to secure perfect fastness of the color) are added

- For printed products printing inks (pigments with carriers and fixatives) are applied

- For multi ply products we often use water soluble glue to secure the intregrity of the product

In most of our mills we do not add optical brighteners but it often occurs in recovered paper since it is used in printing paper.

We do not use softeners for professional hygiene products.

High product quality is secured through quality and hygiene management systems throughout production, storage and transport.

In order to maintain a stable process and product quality the paper manufacturing process is supported by the following chemicals/ process aids:

- defoamers (surfactants and dispersing agents)

- pH-control (sodium hydroxide and sulphuric acid)

- retention aids (chemicals that help to agglomerate small fibers to prevent fiber loss)

- Coating chemicals (that help to control the creping of the paper to make it soft and absorbent)

To reuse broke and to utilize recovered fibers we use:

- Pulping aid (chemicals that help to repulp wet strong paper)

- Flocculation chemicals (that help to clean out printing inks and fillers from recovered paper)

- Bleaching agents (to increase the brightness of pulp from recovered paper)

In the cleaning of our waste water we use flocculation agents and nutritients for the biological treatment to secure that no negative impact on water quality comes from our mills.

Environmental certification

This product is certified for FSC®.

Packaging

Fulfilment of Packaging and Packaging Waste Directive (94/62/EC): Yes

Article creation date and latest article revision

Date of issue: 16-09-2019

Revision date: 27-11-2024

Production

This product is produced at Essity Professional Hygiene NA mill, US.

Destruction

This product is suitable in normal waste handling systems by the community. Used products should not be handled over to recycling systems.

Essity Canada Inc., Cira Centre, Suite 2600 2929 Arch Street, Philadelphia, PA 19104, USA